The History of Oil Drilling: From Ancient Techniques to Modern Marvels

Oil and gas acquisition has a rich and fascinating history that spans centuries, evolving from rudimentary methods to...

By: Superior Performance Feb 20, 2023 2:22:00 PM

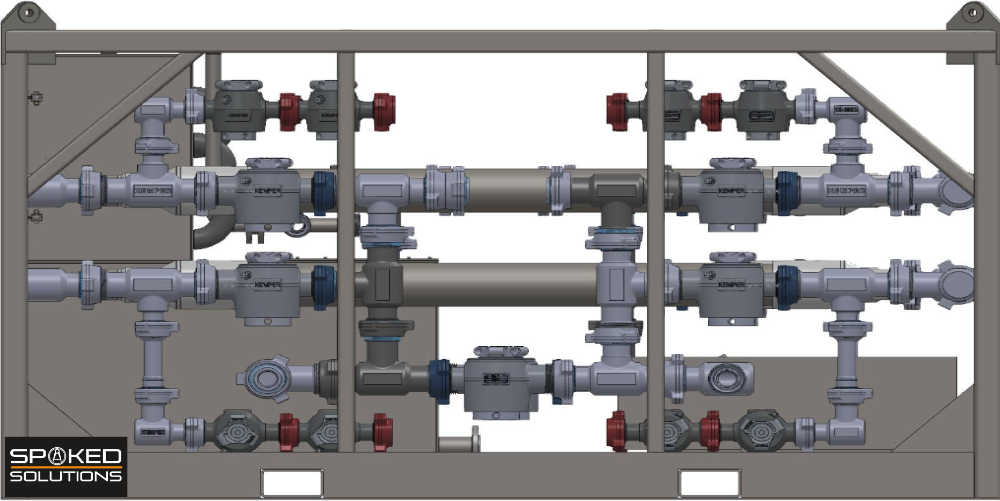

Are you looking for a piece of equipment that can help you protect downhole tools and equipment from damaging completion fluids debris? If so, you may be wondering what a High-Pressure Debris Filtration Unit (HPDU) is and whether one would be the right fit for your business.

In this blog post, we'll define what an HPDU is, why use these units, discuss their benefits, and help you determine if it's the right choice for your company.

High-Pressure Debris Filtration Units (HPDU) help operators protect downhole tools and equipment from damaging completion fluids debris.

HPDUs are designed with unique filtering systems that help remove debris from completion fluids. Similarly, these systems remove small or large solids from pits, valves, pumps, and other equipment before those solids can enter the wellbore.

Downhole equipment is required for deepwater, multizone completions. In these scenarios, individual zone openings and closures must be handled by downhole equipment. If these tools fail to open or shut a zone, operators may lose production from that location.

In these situations, the worst-case scenario is a well loss. Solid debris getting clogged inside the drill bit is a typical reason for downhole tool failure. Drilling operations become far more complicated when debris management is considered.

For this reason, operators need to remove as much debris as possible, protect downhole equipment, optimize flow rates, and mitigate nonproductive time (NPT). HPDUs are the last line of defense from solids entering the wellbore.

Some benefits of using HPDUs at your job site include:

High-Pressure Debris Filtration Units (HPDU) may be designed differently depending on each manufacturer. These design elements are what make these units unique and help them stand out from other manufacturers.

The Superior Performance HPDUs features the following details:

Contain wire wrap screens gauged based on customer mud and brine fluid systems and may be sized to even capture gravel pack sand.

Contain single 3” 1502 WECO connections for inlet/outlet integration to ease and bypassing in the event of severe plugging, thus permitting rates in excess of 18bpm.

Are capable of back flushing individual barrels while still going downhole; eliminating operational pause or preventing downtime during critical pumping operations.

Include an integrated capturing system that allows for inspection of captured debris during the operation.

Include digital gauges used to identify which barrel is experiencing plugging and to allow an accurate gauge of pressure drops for the surface system

May be mobilized for shorter, simple operations due to its compact design or the DPDT-IL may be adapted to a single joint of drill pipe permitting installation on deck, below the top drive, or downhole.

Include screens that may be customized to filter as tight as desired without stripping weighting agents

Operators may conduct on-the-fly back flushing to eliminate downtime

Eliminate valves from HP Iron provider with the use of HP barriers

A bypass line is provided per zone

Operators may conduct on-the-fly inspections of debris

There are no daily consumables

Retesting is not necessary

The Superior Performance High-Pressure Debris Filtration Unit is designed with unique filtering systems that help remove debris from completion fluids. This filtration unit can be installed onsite and helps improve the performance of your entire system.

With this unit, you can reduce wear and tear on pumps and other equipment, improving the overall life of your system. Plus, you’ll get cleaner fluids that will help keep your production rates high.

Contact us today, let us help you with service and getting you the right tool for the job. We go above and beyond and are committed to helping you find the right tool.

At Superior Performance, our team provides drilling contractors and operators with a wide range of construction services to cover most work scopes associated with rig/drilling packages and upgrades, refurbishment, and repair.

We can provide either a turnkey solution or individual work scopes, including Field Service Supervisor assistance, thread inspection services, casing ID caliper services, Laser Tally services, and power equipment.

We also carry premium casing and tubular rental tools in a wide variety of sizes and connections, including elevators for casing and tubing, tubing/casing crossovers, full open safety valves, stabbing guides, casing swages and much more.

Sep 18, 2024

Oil and gas acquisition has a rich and fascinating history that spans centuries, evolving from rudimentary methods to...

Aug 13, 2024

In today’s technology-driven era, lasers have seamlessly woven themselves into our daily lives. From Lidar Technology,...

Jul 11, 2024

1. The Product - CapRite Quickie Protectors™ Superior Performance, Inc. and CapRite Quickie Protectors™: A...