Torque Turn Services

GEN II Torque Control System

The AllTorque torque/turn monitoring system monitors, records and controls the torque, turns, and speed of the power tongs in real time.

This data helps to control tubular connections during makeup and breakout and to ensure that all connections conform to manufacturer specifications.

The AllTorque system gives you the information you need to ensure make-up conforms to manufacturers' specs. You can review results from previous make-ups and create reports for further analysis and information.

Reliable

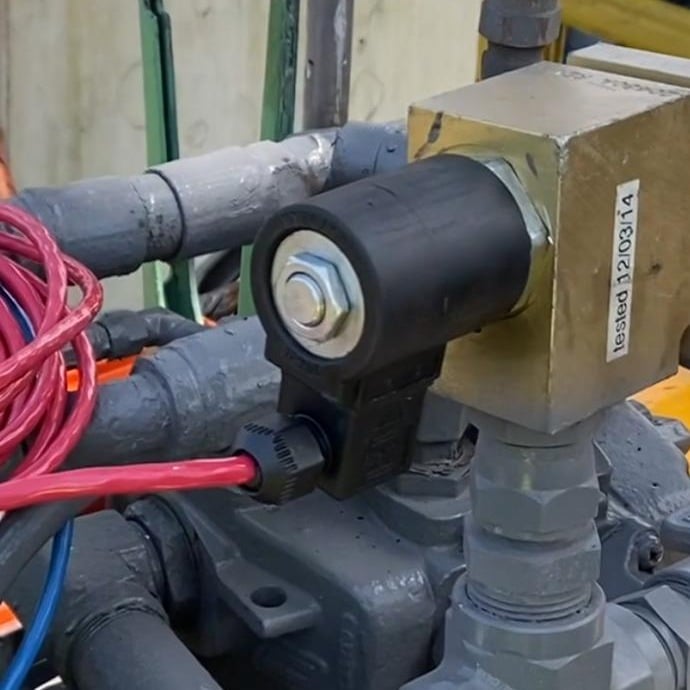

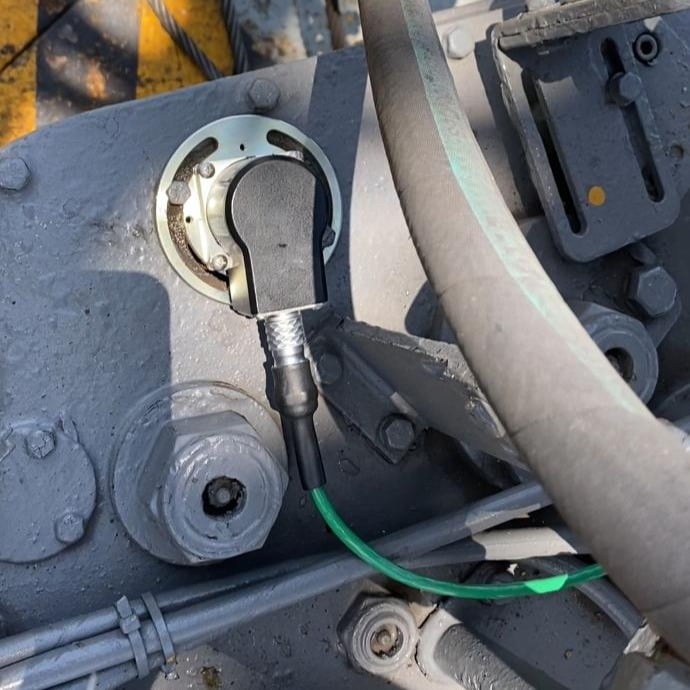

Hardware built for the rig floor

Robust load cells

Real Time cloud data backup

Accurate

Load cells calibrated to <0.1%

Industry leading sample rate >3000 Hz

Easy to Use

Clean and intuitive user interface

Modular plug and play hardware

Step by step training guides

24/7 Technical support

Features

Continuous Recording

Nothing happens without the software recording it. Whether making or breaking a connection, pressure testing, or anything in between, the program seamlessly tracks everything.

Un-Editable Data

Data values are encrypted at the first stage of measurement. Personnel cannot hide or change any of the information seen by the system. Data is backed up and stored securely for 40 years

Live Access

Internet access gives real-time access from anywhere in the world. Controlled access for Operators, TRS Companies and Pipe Manufacturers allows for a view of connection make-up remotely in real time.

Portal

The AllTorque web portal allows for remote access to live jobs and company data without the need for special software. If you can surf the web you can watch a job in the field.

Software Spec’s

Cloud Based Software For Use With Tongs & Aelium Torque Sub

Software Continuously Updated, New Features & Security Touch

Pipe, Accessory, Tong & Hardware Librarys

Automatic Joint Detection & Dumping

Torque, RPM & Shift Control

Continuous Recording

Hardware Spec’s

Power: 110 -220 VAC Input Lithium- ion battery backup with power supply built into system.

Sampling Frequency: 30,000 Hz

Recording Frequency: 30 - 1000 Hz

Dump Valve Response: 10 - 30 ms

Electronic Response: 0.04 ms

Torque Control: +/- 1% of optimum

Turns Accuracy: Typically < 0.1% of 1 Turn on Tong

Operating Temp Comp:

0 - 40 Deg C (32 - 104 Deg F)

Operating Temp Control Box:

-40 - 75 Deg C (-40 - 170 Deg F)